Product Description

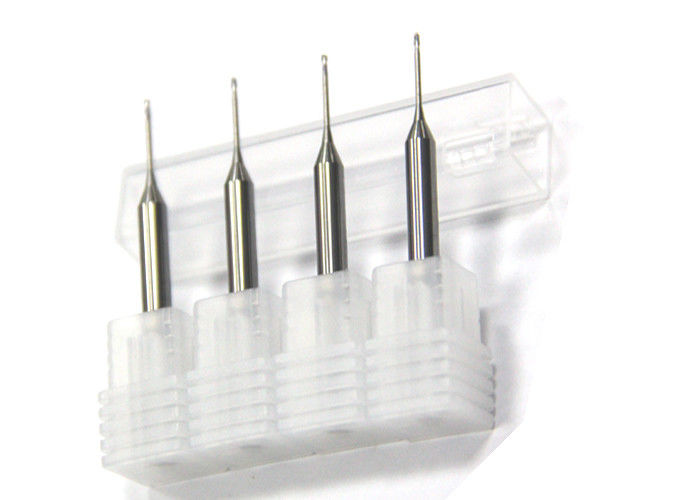

High Speed Steel End Mills Cutting Tools Miniature Carbide Micro End Mill

Specifications

| Raw Material |

AF308/510 |

| WC |

88% |

| Co |

12% |

| TRS |

>4500N/mm2 |

| Hardness |

>92HRA |

| A.O.L |

50mm |

| Grain size |

0.2μm |

| Upto |

HRC60 |

| Flutes No |

2F |

| Coating |

AlTiN or TiSiN |

| Suitable for |

Steel,stainless steel,nickel alloy,Titanium alloy,cast iron,plastic and other materials |

Coating:

| Item |

AlTiN |

TiSiN |

| Hardness(HV): |

3200 |

3600 |

| Thickness(μm): |

2.5-3 |

3 |

| Oxidation Temp(°): |

900 |

1000 |

| frictional Coefficient: |

0.3 |

0.45 |

| Color: |

Black |

Copper |

Deep Groove Standard Sizes: Blade length and closed hole

| Size |

Length of (Flute +Under Neck) |

Flute Length of End Mills(mm) |

| D0.2/R0.1*D4*50 |

1,2 |

0.4 |

| D0.3/R0.15*D4*50 |

1,2,3 |

0.6 |

| D0.4/R0.2*D4*50 |

2,3,4,6 |

0.8 |

| D0.5/R0.25*D4*50 |

2,3,4,5,6,8 |

1 |

| D0.6/R0.3*D4*50 |

3,4,5,6,8 |

1.2 |

| D0.7/R0.35*D4*50 |

3,4,5,6,8,10 |

1.4 |

| D0.8/R0.4*D4*50 |

3,4,5,6,8,10 |

1.6 |

| D0.9/0.45*D4*50 |

3,4,5,6,8,10 |

1.8 |

About Us

Changzhou Xinpeng Tools Manufacturing Co., Ltd. is located in Xixiashu Town, Xinbei District, Changzhou City, Jiangsu Province, China. It is 5km away from Changzhou International Airport and 3km away from Shanghai Nanjing Expressway. The transportation is very convenient.

Adopting domestic and foreign high-quality tungsten steel base materials, the quality of cutting tools has reached the leading level of domestic counterparts, among which several special cutting tools can be equivalent to the quality of world brand cutting tools.

We mainly produce tungsten steel milling cutter, drill, reamer, drill reamer, boring cutter, T-groove milling cutter, chamfering cutter, Corner Radius End Milland other turning, milling and drilling cutters, and designs and manufactures various customized cutters and schemes for customers.

Our end mills are suitable for carbon steel, alloy steel, stainless steel, Quenched and tempered steel, non-ferrous materials, etc. all kinds of cutting tools and application schemes for the manufacturers of automobile, motorcycle engine, diesel engine, carburetor, compressor, mould industry, 3C manufacturing, etc are provided by us. Our end milling cutters are mainly matched with CNC machining center, CNC machine tools and other high-precision machine tools.

The newly launched special forming tools for hydraulic industry, and the product types cover the industry standards of domestic and foreign brand hydraulic leading enterprises (Rexroth, Vickers, sun, Parker, Hydra force, HYDAC, etc.).

FAQ:

1. What’s your payment terms?

A:T/T or L/C.

2. What’s your delivery time?

A:Usually we will arrange the shipment in 7-15 days.

3. How about the packing?

A:Usually we provide the packing as 25kg/bag or carton. Of course, if you have special requirements on them, we will according to you.

4. What is loading port?

A:Usually is Shanghai, Qingdao or Tianjin.

5. Is your company accept customization?

A:OEM and ODM are available. And we have our own professional R&D team servicing for you.

6.If you want to know more about our company?

A:With no Hesitate, directly contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!